April 2019 | Point of View

Accelerating driver productivity to meet evolving consumer delivery demands

Driver shortages and high turnover in the transportation industry are having an impact on delivery performance, operational productivity, and consumer experience

Accelerating driver productivity to meet evolving consumer delivery demands

Executive summary

- Driver shortages and high turnover in the transportation industry are having a marked impact on delivery performance, operational productivity, and consumer experience. With the driver shortage expected to triple by 2026, companies need to be thinking about how to attract new drivers now by adjusting their benefit offerings. However, this action could cause the price of consumer goods, such as toothpaste and diapers, to skyrocket to offset those new benefit costs. Companies like Hershey and Coca Cola have already announced increased prices on their products due to transportation costs.

- Negative customer experiences due to slower delivery timelines, increased costs, or package defects threaten growth and market density – creating an adverse effect on margins and productivity. And the timing couldn’t be worse. The explosive growth of Amazon and others is disrupting industries that are historically slow to innovate and adapt, and competition is stiff no matter where one looks.

- Delivery and transportation functions must develop the will and the skill to improve to compete effectively in this disruptive environment. Having the will to improve means not being afraid to hold drivers accountable for their productivity. Having the skill to improve means having the right optimization tools in place to allow the organization to do more with the same resources, and incorporating training and effective procedures to ensure the tools are used correctly.

- While exciting new technologies come with capabilities for boosting productivity, technology alone will not deliver performance improvement. To meet demands and derive maximum value from technology investments, delivery operations depend on people – from drivers to frontline supervisors to leadership – performing their jobs well. This requires having the right performance management approach in place to help them do so.

Introduction

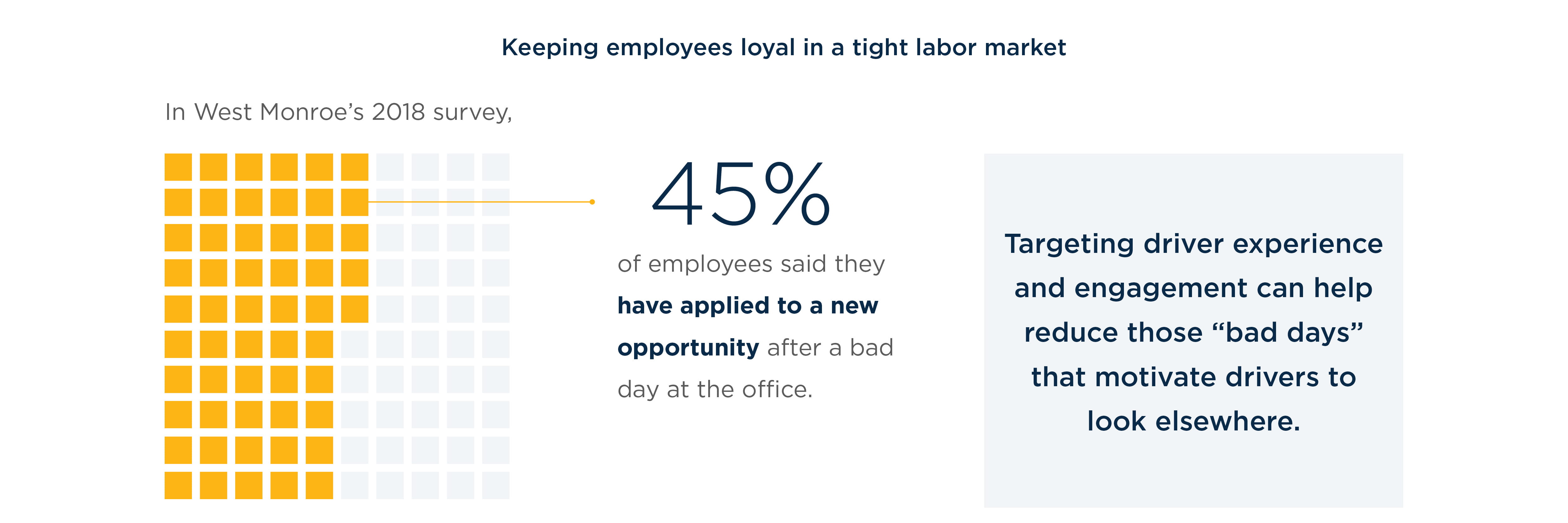

A tight labor market, high turnover, and increasing freight demands have converged to produce a shortage of delivery drivers—a deficit that is translating to higher costs at the same time as innovative competitors, large and small, are disrupting transportation practices. Additionally, private equity (PE) firms have begun investing in the transportation and logistics (T&L) industry at increasing rates, with T&L acquisitions jumping 44 percent between 2015 and 2017. The result is often that newly acquired companies are enabled to accelerate growth through innovation and investment—which can leave other companies struggling to keep pace. And as organizations look for ways to reduce delivery costs and boost driver productivity in this disruptive environment, they risk alienating the drivers on which they depend.

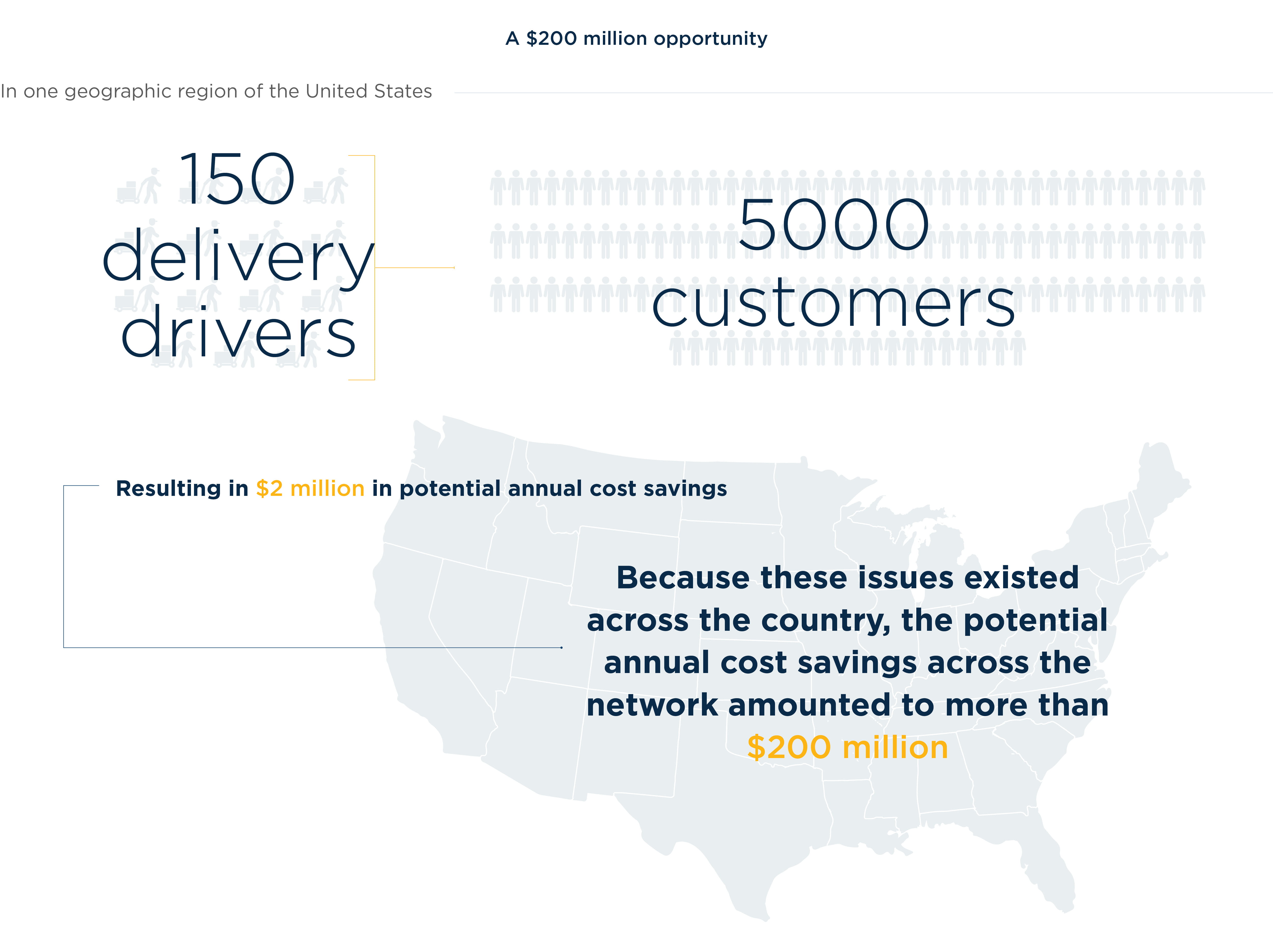

For transportation and delivery function leadership, frontline management, and engineers, increasing driver productivity does not have to conflict with efforts to attract and retain delivery drivers. In fact, a successful performance management program, bolstered by technology, data-driven modeling, and work measurement, effectively addresses both objectives when designed and executed correctly. We have seen such efforts boost productivity by as much as 30 percent.

Unmet demand for drivers is fueling wage competition, high turnover, and increased costs

Continued U.S. economic growth has had a positive effect on the labor market in many industries, adding new jobs at a record pace. For example, according to the Bureau of Labor Statistics, the manufacturing industry added 284,000 net-new jobs last year, its largest annual gain since 1997. While this kind of stability has obvious benefits, it creates some unique challenges for delivery operations.

First, it fuels strong consumer demand, which in turn drives an increased need for enhanced and expanded transportation and delivery capabilities. With behemoths like Amazon, Wal-Mart, and Target continuously disrupting practices for transporting and delivering goods, organizations must strive to increase agility while meeting customer expectations for even faster and cheaper delivery.

Second, low unemployment (in September 2018, the U.S. unemployment rate hit its lowest point in 47 years, at 3.7 percent) has a marked impact on the transportation workforce and, particularly, drivers. According to data from the American Trucking Associations, America’s shortage of truck drivers exceeded 50,000 at the end of 2017, an increase of nearly 15,000 from the previous year. With the unemployment rate remaining steady at 3.8 percent at the end of March 2019, it is fueling a rapid increase in driver compensation and, in turn, increased shipping/delivery costs. For example, DAT Solutions data (2018) revealed that it costs more than $1.85 per mile to ship a ‘dry good’ that doesn’t require refrigeration or special accommodation, an increase of nearly 40 percent in one year.

Build a performance management “cycle” that targets productivity and cost while engaging drivers

Addressing the dual—but potentially conflicting— objectives of driver retention and engagement and productivity or cost reduction requires a carefully designed performance management approach. Specifically, this entails four stages of activities that form a self-sustaining, closed-loop “cycle” which drives continuous improvement.

1| Set sound and credible performance expectations

Performance expectations are a critical prerequisite that allow the workforce, supervisors, and managers to measure and achieve success.

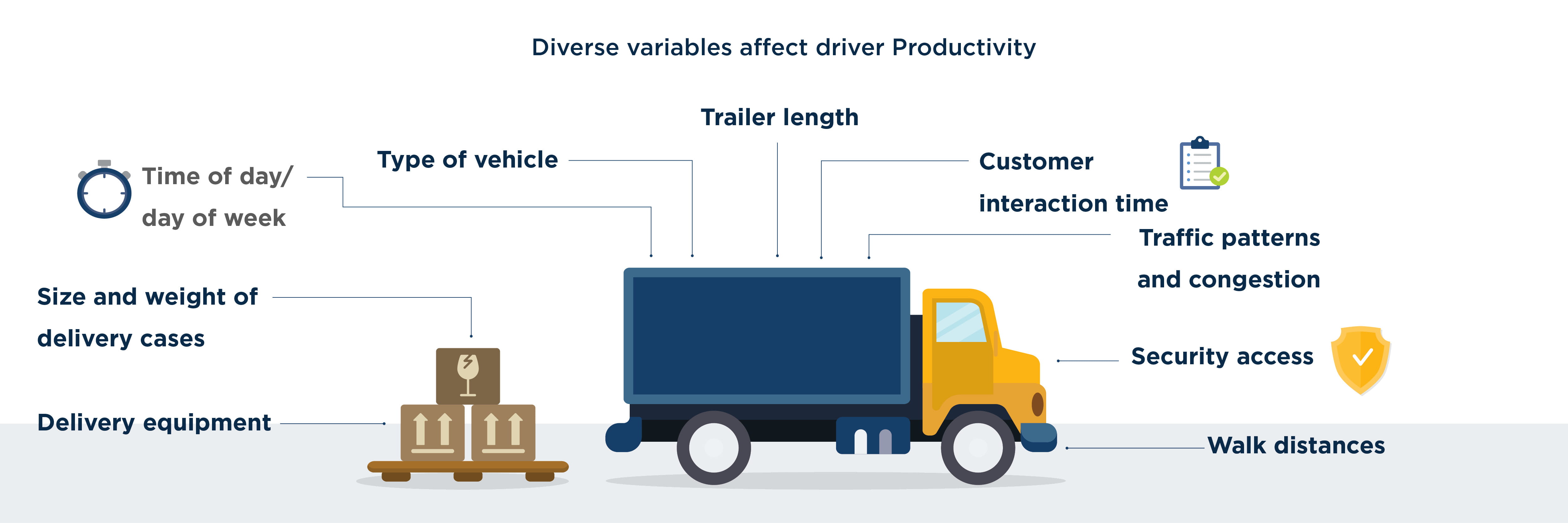

While many distribution organizations have robust, engineered workforce solutions inside their walls, they are much further behind once the product is on its way to the customer. Delivery operations are complex. Traditional production metrics such as “cases per hour” and “time per stop” are appropriate expectations at a high level, but spreading them like peanut butter across unique operations, routes, and delivery stops is a major underlying cause for the problems that delivery organizations are now trying to solve. They foster a lack of faith in metrics, disengagement among drivers, poor delivery window adherence, and, ultimately, a risk to customer experience.

Setting expectations based upon the true content of delivery work is transformational. It enables leadership to measure the true estimated cost of work, accounting for all variables necessary to drive improvement and reward success. For example, drivers can earn bonus or incentive pay based upon their skill and effort. Historically, bonus programs that are based solely on production metrics fail to deliver results, as they often focus on data that is based on averages across all driver groups and do not accurately represent individual drivers or routes. Rather, our experience has shown that implementing an engineered approach to work measurement combined with an incentive-based pay program increases productivity by up to 30 percent—with the potential to unlock even greater gains.

Technology for managing delivery processes has come a long way and can produce timely data that hasn’t always been available. These data-driven tools play an important role in setting performance expectations—but they tend to be underutilized. Implementing data and technology solutions such as real-time telematics and transportation management systems allows engineers to model the complexities and variances that exist in delivery operations much more accurately than before.

2| Monitor the environment and conditions

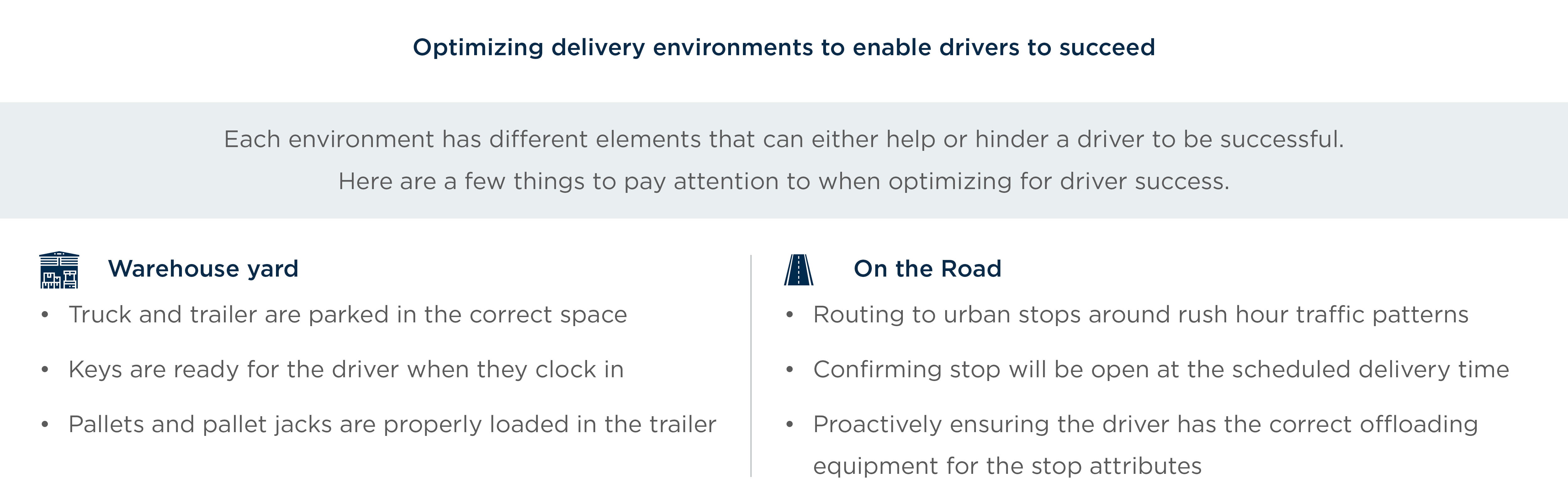

With expectations based on an engineered work measurement framework, it is important to ensure the work environment is set up to make employees successful. This means equipping drivers with tools, equipment, standardized methods, training, and the work environment they need to meet expectations.

Regular environmental monitoring helps separate driver performance from job set-up issues so that leaders can take appropriate actions to solve for each. Frontline supervisors assess adherence to standard procedures by using on-the-job observation tools, such as real-time driver route monitoring, performance metrics measured by in-vehicle computers, telematics like GPS tracking units, or in-field driver observations. They also document variances and engage the driver for review. Management is responsible for creating and maintaining the proper environment and conditions. Effort spent towards assessing adherence is based upon exposed gaps in productivity, as well as specific changes that have occurred. It must be consistent and objective in order for it to generate support and succeed.

Technology and systems that support the execution of the key steps above afford organizations scalability and increased sustainability of their performance management programs. However, large-scale investment in new systems, which is often a barrier to implementation, is not always necessary to begin realizing productivity improvements. Increasing productivity is possible first and foremost as a result of management teams’ execution of the key steps discussed. These simple concepts, when executed concurrently, can improve complex delivery processes.

Productivity improvements realized from ensuring optimal environment and conditions far outweigh the efforts invested by management. Taking the time to ensure basics like ensuring the truck and trailer are parked in the correct space, the keys are ready for the driver when they clock in, and pallets and pallet jacks are properly loaded in the trailer can yield large returns. We have found that properly monitoring environment and conditions can produce incremental savings of up to 5 to 10 percent.

Metrics and data can help drivers perform more effectively, but these also can highlight barriers that must be removed in order to meet expectations. For example, in delivery operations, there are often opportunities to improve productivity and reduce costs by updating routing. Designing optimized routes and properly loading them in the warehouse are not issues that a driver can fix. Furthermore, enforcing metrics while failing to remove these barriers can have a significant negative effect on driver morale and engagement.

3| Assess results

Labor modeling software and business intelligence analytics platforms enable stakeholders to see real- time and historical performance versus expectations to identify paths to improvement. This makes supervisors more effective in their roles because they can clearly and quickly see results in a variety of ways and identify corrective actions.

Different issues require different problem-solving approaches. A driver’s productivity could be low because he is moving too slowly, the routing caused him to drive more miles than necessary, the trailer was loaded improperly—requiring extra handling time—or because 20 percent of his time was spent waiting at the customer site due to delivery window commitments. Each of these issues requires a different solution. Without the right reporting, however, this driver may have struggled under the radar because leadership was content with his overall “cases per hour” compared to the average. Worse yet, he may have been unfairly targeted for performance issues or firing—or at risk for leaving because factors affecting his reward or compensation were beyond his control.

4| Respond to performance issues—and recognize outstanding performance

Timely investigation, response, and corrective action is essential to continuous improvement and is the final step in the closing the cycle of managing driver performance. This step is easier said than done, however. Most supervisors already have an array of new “fires to fight” every day, so making the time to enforce performance management tends to drop to the bottom of the list.

Furthermore, organizational culture can be a major inhibitor to appropriate response. Many frontline supervisors and managers lack the skills, confidence, and supporting data to have difficult conversations with drivers—conversations that can be further complicated by generational differences. Being able to conduct meaningful, action-oriented performance discussions is a managerial skill lacking across many industries. However, the combination of fair expectations and accurate data can equip managers with confidence and ease the difficulty level.

This step is particularly important to improving performance and tackling issues of driver retention. Historically, efforts to manage driver performance can add tension to the relationship between drivers and management. Drivers lack confidence in management’s ability to accurately assess performance due to absence of detailed work measurement and overall lack of visibility into the driver’s day. When managers are equipped with the proper tools to provide timely, specific feedback on performance, trust grows. Drivers see clear evidence that the management team is working to remove obstacles that may hinder their productivity and create a work environment when they are recognized individually for their performance, including monetary incentives and additional accrued time off.

Finally, remember that performance management, in any context, is cyclical. The output of efforts to monitor and improve performance then become inputs for updating expectations. Thus, the cycle begins again.

Take the next steps to creating a win-win environment for your delivery operations, drivers, and consumers

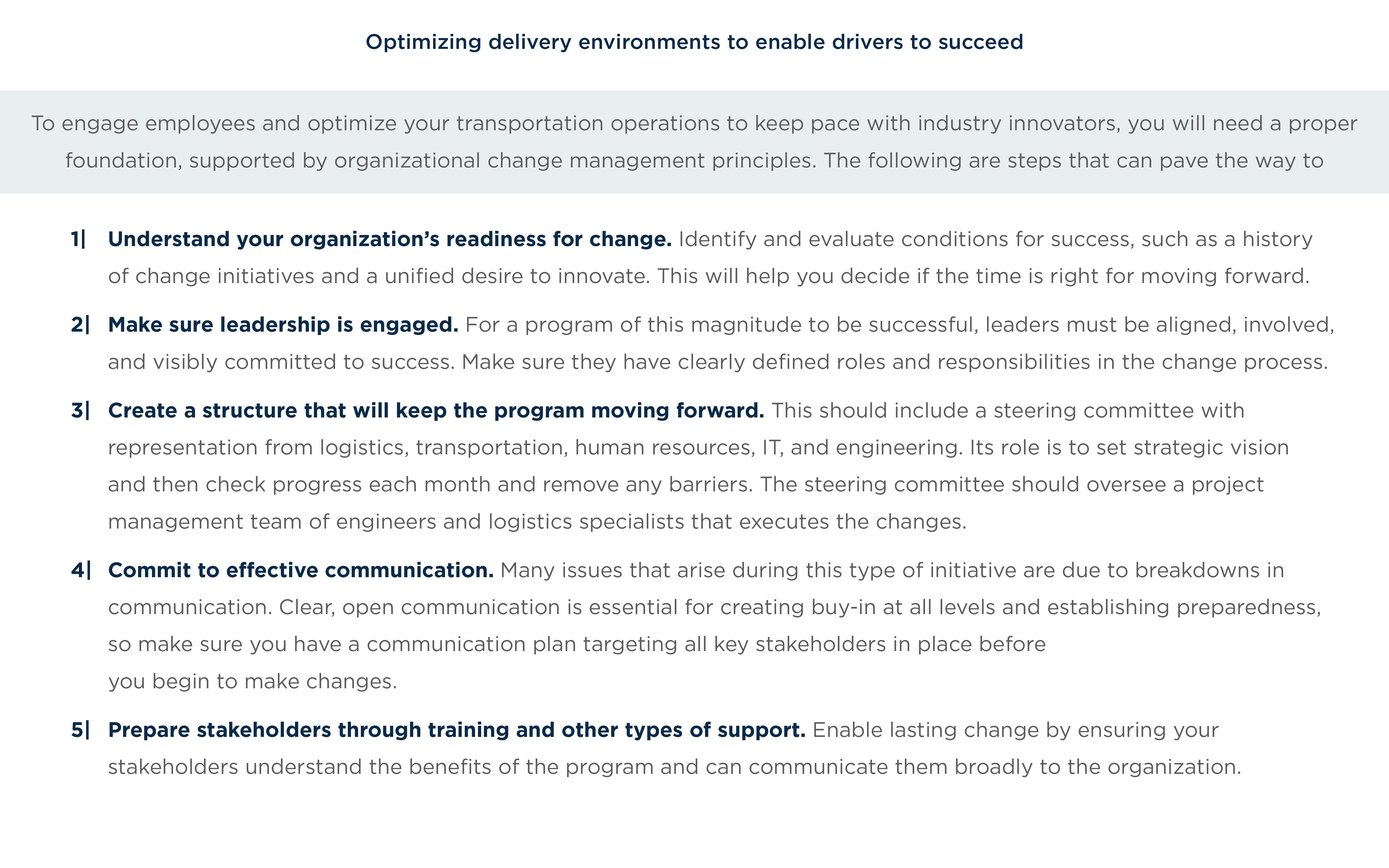

From our experience working in diverse delivery and transportation operations, we have seen organizations that transform driver experience successfully deliver annual productivity gains of 15 to 30 percent through increased throughput and/or reduction in labor hours. Such improvement is alluring—but recognize that actually delivering gains of that magnitude requires a well-conceived and proactive approach for designing and managing change. Your organization will need to develop both the will and the skill to change.

To tackle this issue, you will need a foundation of knowledge and best practices around workforce optimization, employee engagement, and work measurement for distribution and delivery operations. West Monroe has extensive experience that can support you in this area.

You will also need to have a foundation in place to support and sustain change. That starts with a vision and objectives on which your organization and leaders agree. We have found it beneficial to gather key leaders and stakeholders in a workshop to address these questions: Where are we now? What is our improvement opportunity? What does the future look like? How will we measure success?

This discussion should consider:

- Culture, past ability to execute change, and potential unforeseen impacts and constraints

- Desired outcomes and benefits from the project

- Formal key performance indicators that will help leaders and associates understand what success looks like and how it will be measured

- Enablers and barriers to success

From there, traditional organizational change management principles, including leadership engagement, communication, and an adequate support structure creates a foundation for successful change. Having this foundation will make it easier to begin moving toward a win-win environment for your delivery operations, drivers, and customers—one that targets your cost and productivity goals while also creating a positive environment that attracts and retains drivers in a tight labor market.

.jpg?cx=0.5&cy=0.5&cw=910&ch=947&hash=D82C31B87A38F6B94D04577BA76A2109)